How To Clean Aluminum For Tig Welding

Cleaning upwards aluminum before welding is essential to make sure that the end product is structurally strong. If you've washed your inquiry on how to all-time practice it, yous probably establish the aforementioned data everywhere:

- Remove grease and oil using a liquid degreaser. This includes solvents or mild alkaline metal solutions like acetone and lacquer thinner.

- Dry the surface with a make clean cloth.

- Remove the aluminum oxide layer with a stainless steel wire brush.

This manual method is skilful but time consuming. For many welders, finding an alternative method is crucial to spend less time on transmission cleaning. One of these methods is light amplification by stimulated emission of radiation cleaning.

Permit Us Know Your Application

How Does Laser Cleaning Work?

How Does Laser Cleaning Work?

Light amplification by stimulated emission of radiation cleaning, too known as laser oxide removal, removes all types of contaminants at one time. When the laser beam hits the aluminum surface, grease, oil, dirt and aluminum oxides are all vaporized into dust and fumes. The light amplification by stimulated emission of radiation sends the right amount of energy to remove those contaminants without introducing impurities in the aluminum.

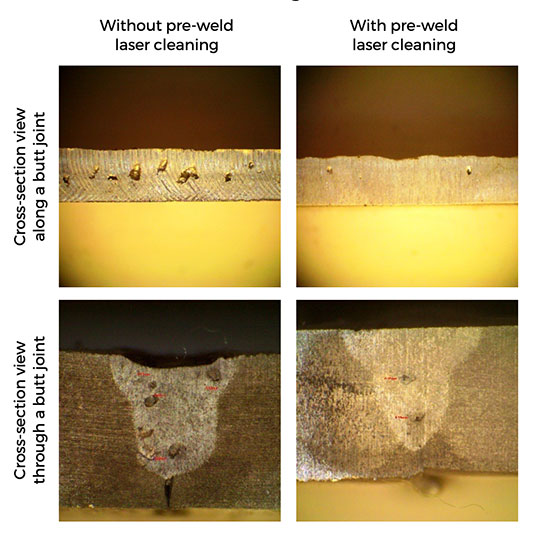

The resulting weld quality is splendid. As shown in our report on light amplification by stimulated emission of radiation cleaning for welding, laser cleaning significantly reduces the number and the size of porosities in the weld joints. You can run across the results obtained with and without pre-weld cleaning.

A broad range of laser cleaning solutions exist. Some of them are handheld while others are fully or semi-automatic. To give yous an thought of the potential of light amplification by stimulated emission of radiation cleaning in welding applications, y'all tin watch the post-obit video.

Is Light amplification by stimulated emission of radiation Cleaning Always a Good Choice When Welding Aluminum?

Merely put, no. Laser cleaning is not always a adept solution. The cleaning method needs to exist chosen on a case-past-case basis. People who buy a light amplification by stimulated emission of radiation to clean their welds normally practice so because they get a high return on investment, relieve time, and obtain high-quality results. However, lasers require an initial investment that is simply worth it if you process enough parts.

Contact a Laser Expert

What Are the Other Pre-Weld Cleaning Methods?

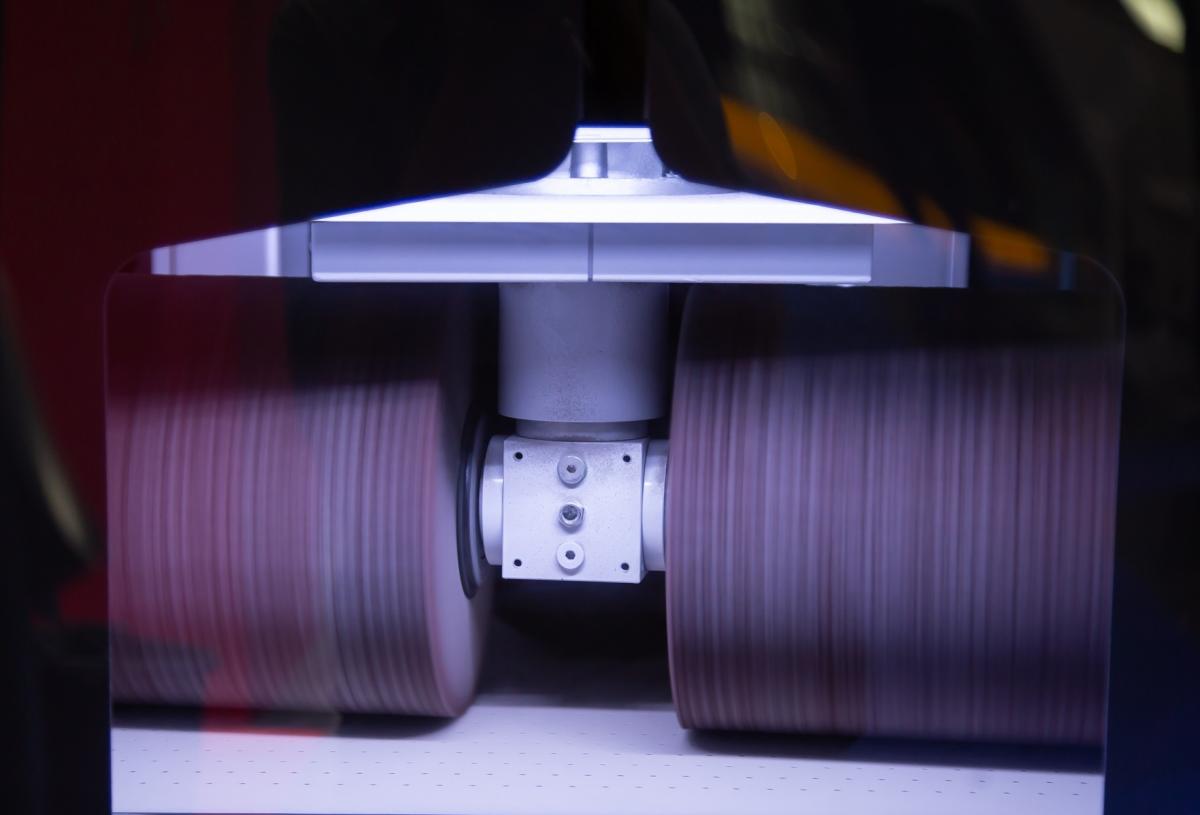

Mechanically removing oxides using rotating brushes is usually a good alternative when lasers aren't fast plenty, which can be the instance when cleaning thick oxide layers and large surfaces.

Mechanically removing oxides using rotating brushes is usually a good alternative when lasers aren't fast plenty, which can be the instance when cleaning thick oxide layers and large surfaces.

Electrochemical oxide removal is also widely used, although an increasing number of welders are moving away from chemicals, as they are expensive, chancy and hard to manage.

If you're interested in learning more than most these methods, read our post on removing oxide from aluminum.

Tips for Preparing Aluminum for Welding

Whether you're doing TIG welding, MIG welding or any other blazon of welding, at that place are things yous should always practise, and others y'all should avoid. Miller, an important manufacturer of arc welding products, provides useful tips on how to create high-quality aluminum welds.

Trying to weld with muddy base and filler metals adds unnecessary difficulty and can atomic number 82 to poor weld quality. You as well have to deal with the natural oxidation that takes place with aluminum. Suitable training prior to welding is important.

Excerpt from What Y'all Need to Know About Cleaning and Preparing Aluminum Filler and Base Metals Earlier Welding past Miller

In their article, they provide tips to assist you protect the welds from contaminants that could mix with the weld puddle, even if yous cleaned the surface properly. Some of these contaminants include hydrocarbons and wet that can cause lack of fusion, lack of penetration, and porosity.

If you're using laser cleaning, you can ignore Miller's tips on how to clean aluminum before welding, every bit they utilize a manual method. We've summed up beneath the things you should and should not do if you are a laser user.

Things You Should Do

- Store your filler and base materials in a dry location where temperature is regulated

- Store your aluminum parts vertically

- Bring your filler and base metals in advance into the welding expanse to permit them to reach room temperature

- Keep your filler materials covered until the last minute

- Use plasma arc cutting or laser cutting to cut the parts to exist welded

- If you're working with aluminum alloys from the 2000, 6000 or 7000 series, remove 1/8 of an inch from the melted edges that result from cut

Things You lot Should Not Do

- Do not cutting aluminum parts to exist welded using methods that leave a smeared or ground surface (for instance, avert grinders)

- Do not utilise lubricants when cutting aluminum parts to be welded

- Do not preheat the parts to be welded using oxyfuel or carbon

- Do not use compressed air to blow grit off the joints

- Do not wipe the parts to be welded using store rags

What to Exercise Subsequently Welding

After the welding procedure is over and you've done everything right to prevent contaminating the welds, your job isn't over. You lot still need to make clean the oxide byproducts generated during welding. You may have washed this before using a wire castor. However, y'all can also remove these oxides using laser cleaning.

If you're interested in laser cleaning to remove oxides for welding applications, contact our experts to discuss your application.

Contact a Laser Expert

Source: https://www.laserax.com/blog/cleaning-aluminum-welding

Posted by: duvalldifors.blogspot.com

0 Response to "How To Clean Aluminum For Tig Welding"

Post a Comment